HighLift by

Olvondo Technology

is unique as the world’s first near-market industrial high temperature heat pump based on a reversed Stirling engine design.

This represents a radically different technology to anything that is on or near to market today.

Stirling technology facilitates a paradigm shift by supplying significantly higher output temperatures that are required for a myriad of industrial processes in a manner that is independent of fossil fuel sources.

«The advantage of HighLift technology are the financial and environmental gains achieved through savings on cost and emissions of alternate energy sources»

The project will adress and implement the technical and commercial roadmaps that we have developed with AstraZeneca and other industrial test users to enable a rapid and successful commercialization of HighLift.

Technology maturation & final prototyping objectives (WP1)

to optimize HighLift subsystems, integrate them into an improved HTHP prototype and undertake a detailed simulation of the full system function. We thereby aim to raise the TRL of our technology from its current TRL7 to TRL8.

Piloting & validation objectives (WP2)

to demonstrate and validate technical performance and benefits through a large-scale pilot in industrial settings with Consortium partner AstraZeneca, elevating HighLift from TRL8 to TRL9.

Commercialization readiness objectives (WP3-5)

enable us to successfully bring the HighLift produkct to the market and reach sales traction beyond the proposed EU H2020 FTI project

TECHNOLOGY MATURATION

WP1 Technology maturation

WP2 Large-scale piloting

MARKET MATURATION

WP3 Supply chain development

WP4 Commercialisation and communication management

WP5 Project & innovation management

Implementation of Commercial Plan Commercial innovation activities: Securing BA/VC funding, sourcing of suppliers, etc.

MARKET LAUNCH

HighLift technology concept

HighLift R&D begins

TRL 1 - 2 HeighLift is developed to meet industry need for cleaner high temperature (>160°C) heat e.g. for steam driven processes OT founded as Single Phase Power AS

Prototype 1 & 2

TRL 3 - 4 First complete pump prototypes are assembled and demonstrated at TINE. Validated max. Carnot coefficient of performance. Deviation from modeled power consumption 4-8%.

Prototype 3 full system

TRL 5 First full installation to user auxiliary systems undertaken at Lerum. 3 full installations at AZ R&D center in Sweden. Validated service interval 1500h, max COP 45%

Prototype 4

TRL 6 - 7 Validated with test user - 4000h service interval, max COP 50%. TINE per unit steam purchase agreement negotiated

Phase 2

TRL 8 - 9 HighLift market prototype: Ready for wide market introduction. Target performance indicators: service Interval 8000h max COP 60%.

Exploitation

Direct sales of HighLift to target customers. Escalation in HighLift sales with partnerships to international agents.

Latest updates

-

High temperature heat pumps in an environmental context

Energy and cost efficient, high temperature heat pumps are increasingly turned to as an environmentally friendly alternative to traditional fossil fuel based options.

-

HighLift heat pump project summary video

The HighLift heat pump has been installed at AstraZeneca’s R&D centre in Gothenburg since 2017. The industrial high temperature heat pumps are now considered an important tool in AstraZeneca’s sustainability efforts, and this video documents just some of the many benefits a HighLift heat pump can have for reducing CO2 emissions in industry.

-

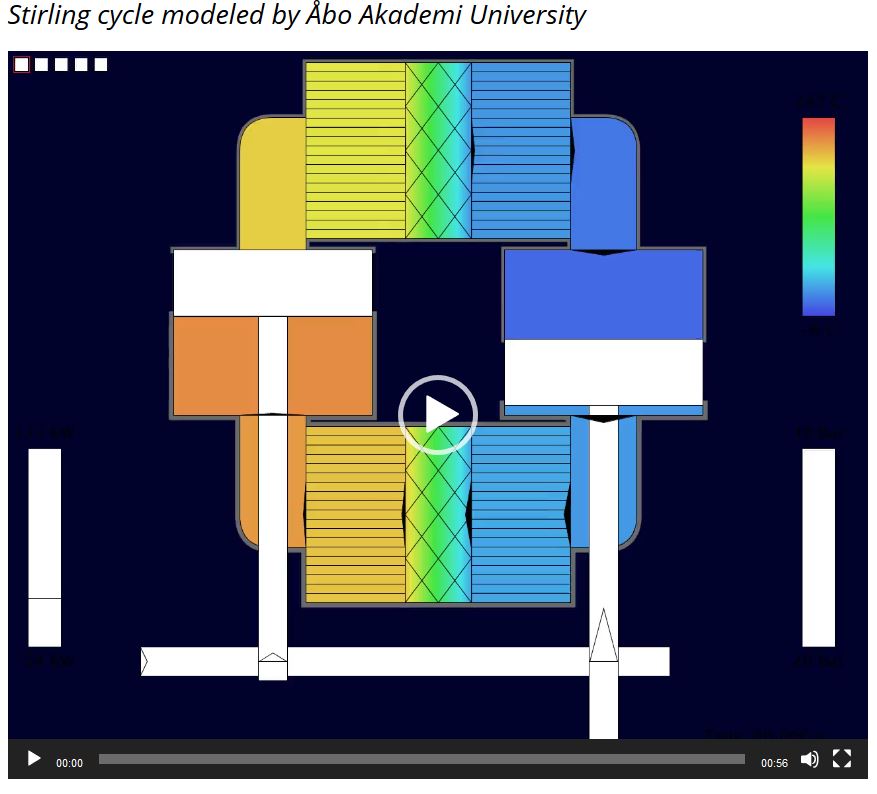

Simulation of pressure imbalance phenomena in a double-acting α-cycle Stirling engine

This article presents an exploratory process of finding root causes of an undesirable pressure imbalance in an industrial high temperature heat pump based on a reverse Stirling engine using a simulation model of the process.

-

HighLift Project to present at ECEEE Industrial efficiency, Gothenburg Sweden 2020

Environmental impact of high temperature industrial heat pumps – from a global warming potential (GWP) perspective

-

HighLift Project to present at IEA HP 13, Jeju South Korea, 2020

Environmentally friendly steam generation using VHTHPs at a pharmaceutical research facility

-

HighLift Project presenting at the ECOS2020, Osaka Japan, 2020

Performance improvement of an industrial Stirling engine heat pump

-

2019 Jiangsu-Norway Green Tech.

HighLift by Olvondo presented on 2019 Jiangsu-Norway Green Technology & Maritime Equipment Project Matchmaking Workshop, November 7, 2019 Nanjing, China

-

Stirling process model

Stirling cycle modeled by Åbo Akademi University

-

Project kick-off

Sucsessful project kick-off at AstraZeneca in Mölndal, December 5, 2018.